HOME > WORKS Test

About the Inspection

We support various non-destructive inspections and dimension measurements according to customer requests, providing safety and security of products and structures.

We support dimension measurements of precision parts in a temperature-controlled room maintained at 20 degrees Celsius ±0.5.

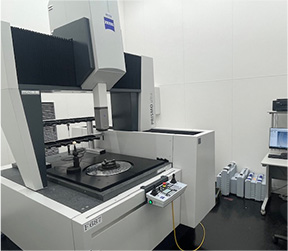

High-precision CMM(PRISMO ULTRA)

-

-

Achieved the highest level of precision measurement.

The top-end model in the ZEISS PRISMO series.

CMM was born to meet the extremely high precision requirements for tasks such as

researching and developing high -precision components, calibrating inspection of standard gauges.

Our PRISMO also comes with a rotary table.

-

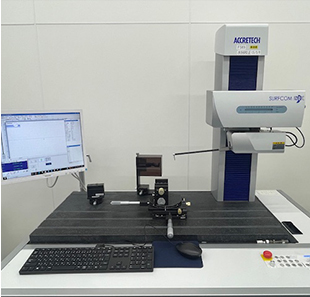

Surface texture and contour measuring machine (SURFCOM NEX 040 DX2-14)

Efficiently evaluate inclined planes and undulating shape, surface roughness and contour shapes with R surfaces in one trace.

-

Semi-automatic roundness and cylindrical shape measuring machine

(RONDCOM NEX 200 DX2-14)

Top class high-precision roundness and cylindrical shape measuring machine equipped with comprehensive features to meet the demands for high-precision measurement of machined parts.

-

Surface texture measuring machine

(SURFCOM NEX 001 DX2-13)

Measuring a wide variety of workpieces under varying temperature environments in a short period of time "Achieved low vibration and high definition measurement by employing linear motor drive"

-

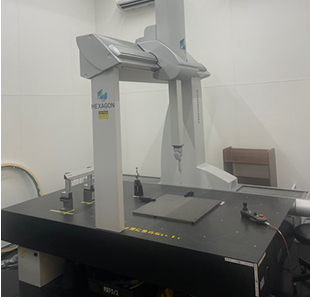

CMM (GLOBAL Performance)

It is possible to achieve high-precision measurements with a structure that is both optimal and excellent in high rigidity than machines of the same size. The Tricision structure enables highly accurate measurements because placed the gravity of the machine close to the measurement target.

-

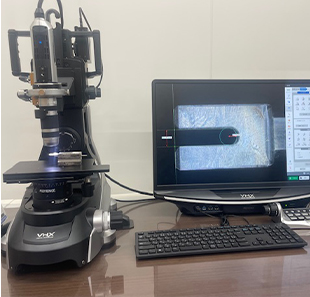

Microscope

(VHX-8000)

This microscope is excellent and is equipped with advanced observation capabilities and versatile analysis functions, equipped with high-precision image observation and automatic focus and can be used in a wide range of applications.

-

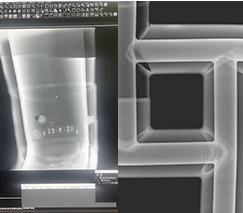

Radiographic Testing

It is possible to detect the presence and shape of defects by irradiating the specimen with radiation and developing the differences in the intensity of the transmitted radiation as shades of light and dark on the film.

- Digital image

processing equipment

Transparent photo

- Digital image

-

Magnetic Testing

Ferromagnetic material is magnetized if there is a defect on the surface or nearby, magnetic flux leaks occur. By detecting the leaked magnetic flux using magnetic particle (powder of ferromagnetic material),it is possible to determine the location and shape of the defects.

- yoke method

-

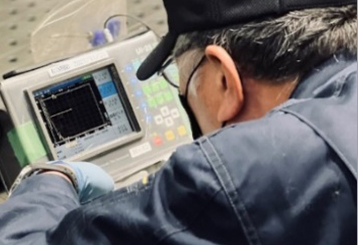

Ultrasonic Testing

When there are internal defects in the test object, the ultrasonic waves that are incident on the specimen will be reflected or scattered by the defects. We will use this phenomenon to inspect the presence and shape of internal defects.

- Flaw detection of metal material

- Flaw detection of welds

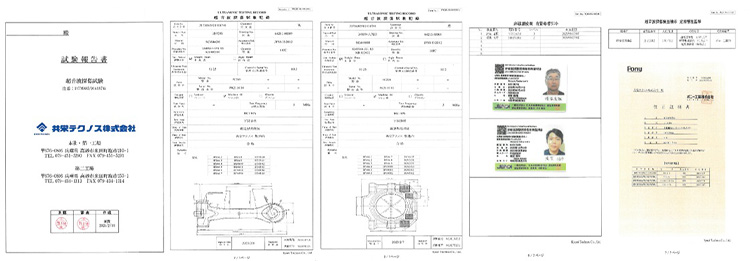

Quality assurance servive

・Inspections cannot be performed due to the absence of non-destructive testing technician.

・Delays in the inspection process occur due to a shortage of inspector.

・The cost of measuring instruments is so high that they are unaffordable, making measurement impossible.

・It is too difficult to measure complex shapes, making evaluation impossible.

These are the problems that is always faced in manufacturing.

To address these challenges,

Our company offers subcontracted inspection services to assist in quality assurance for parts meticulously crafted by our customers. Utilizing own equipment and the techniques we have developed, we provide precise measurements, non-destructive testing, inspection representation for customers, both domestic and international on-site inspections, and optimal proposals tailored to your needs, including on-site visits to plants. The product inspections you request will be handle by qualified personnel, and the quality will be guaranteed through test reports.

Test report (Ex.)

| American Society for Non-Destructive Testing ASNT 9712 |

Penetrant Testing Technician(PT) | Level 2 | 1 |

|---|---|---|---|

| Radiographic Testing Technician(RT) | Level 2 | 1 | |

| Ultrasonic Testing Technician(UT) | Level 2 | 1 | |

| Magnetic Testing Technician(MT) | Level 2 | 1 | |

| Japan Society for Non-Destructive Inspection Non-Destructive Testing Technical Qualifications |

Penetrant Testing Technician(PT) | Level 3 | 2 |

| Radiographic Testing Technician(RT) | Level 3 | 4 | |

| Ultrasonic Testing Technician(UT) | Level 3 | 2 | |

| Penetrant Testing Technician(PT) | Level 2 | 28 | |

| Radiographic Testing Technician(RT) | Level 2 | 8 | |

| Magnetic Testing Technician(MT) | Level 2 | 11 | |

| Ultrasonic Testing Technician(UT) | Level 2 | 10 | |

| Eddy Current Testing Technician(ET) | Level 2 | 5 | |

| Leak Testing(LT) | Level 2 | 1 | |

| Ministry of Health, Labor and Welfare Labor Standards Bureau |

X-ray Operations Supervisor | 7 | |

| γ-Ray Operations Supervisor | 4 | ||

| Mechanical inspection technician(Level 1) | 2 | ||

| Mechanical inspection technician(Level 2) | 5 |

| American Society for Non-Destructive Testing ASNT 9712 |

Penetrant Testing Technician(PT) Level 2:1 |

|---|---|

| Radiographic Testing Technician(RT) Level 2:1 | |

| Ultrasonic Testing Technician(UT) Level 2:1 | |

| Magnetic Testing Technician(MT) Level 2:1 |

| Japan Society for Non-Destructive Inspection Non-Destructive Testing Technical Qualifications |

Penetrant Testing Technician(PT) Level 3:2 |

|---|---|

| Radiographic Testing Technician(RT) Level 3:4 | |

| Ultrasonic Testing(UT) Technician Level 3:2 | |

| Penetrant Testing Technician(PT) Level 2:28 | |

| Radiographic Testing Technician(RT) Level 2:8 | |

| Magnetic Testing(MT) Technician Level 2:11 | |

| Ultrasonic Testing(UT) Technician Level 2:10 | |

| ET:Eddy Current Tensting Technician Level 2:5 | |

| Leak Testing(LT) Level 2:1 |

| Ministry of Health, Labor and Welfare Labor Standards Bureau |

X-ray Operations Supervisor 7 |

|---|---|

| γ-Ray Operator 4 | |

| Machinery inspection technician(Level 1) 2 | |

| Machinery inspection technician(Level 2) 5 |

| Penetrant Testing(PT) | ・Fluorescent penetrant testing for solvent remover of gas turbine parts welds |

|---|---|

| ・Staining penetrant testing for solvent remover of gas turbine parts welds | |

| ・Staining penetrant testing for solvent remover of vehicle-related aluminum products welds | |

| Radiographic Testing(RT) | ・X-ray radiographic testing of double piping welds |

| ・X-ray radiographic testing of medium-sized cast parts after repair | |

| ・X-ray radiographic testing of aluminum castings | |

| ・X-ray radiographic testing of gas turbine parts welds | |

| ・X-ray radiographic testing of various pipe welds | |

| Magnetic Testing(MT) | ・Magnetic testing for large cast parts using prod method |

| ・Magnetic testing for large gear welds in construction machinery using yoke method | |

| ・Magnetic testing for vehicle parts welds using yoke method | |

| Ultrasonic Testing(UT) | ・Boiler-related thickness measurements |

| ・Ultrasonic testing for forging material using nomrmal beam method | |

| ・Ultrasonic testing of large gear welds in construction machinery using angle beam method | |

| ・Mitsubishi-made cast parts thickness measurements | |

| Quality assurance service | ・Major manufactures quality assurance (3D measurement CMM,visual Inspection,record keeping,shipping,packaging) |

| ・Third party non-destructive testing services for small and medium-sized manufactures | |

| ・Outsourcing dimension measurement setvice for precision machined parts by a metal parts manufacturing companies | |

| Dispatch of inspectors | ・Overseas dispatch of non-destructive inspectors |

| ・On-site support and dispatch of non-destructive inspectors for various plant periodic Inspection projects | |

| ・Outsourcing non-destructive Inspectors and technical staff dispatch support to major Inspection companies |

| Penetrant Testing(PT) | ・Fluorescent penetrant testing for solvent remover of gas turbine parts welds |

|---|---|

| ・Staining penetrant testing for solvent remover of gas turbine parts welds | |

| Staining penetrant testing for solvent remover of vehicle related aluminum products welds |

| Radiographic Testing(RT) | ・X-ray radiographic testing of double piping selds |

|---|---|

| ・X-ray radiographic testing of medium-size cast parts After repair | |

| ・X-ray radiographic testing ofaluminum castings | |

| ・X-ray radiographic testing ofgas turbine parts welds |

| Magnetic Testing(MT) | ・Magnetic tasting for large cast parts using prod method |

|---|---|

| ・Magnetic testing for large gear welds in construction machinery using yoke method | |

| ・Magnetic testing for vehicle parts welds using yoke method |

| Ultrasonic Testing(UT) | ・Boiler-related thickness measurements |

|---|---|

| ・Ultrasonic testing for forging material using nomrmal beam method | |

| ・Ultrasonic testing of large gear welds in construction machinery using angle beam method | |

| ・Mitsubishi-made cast parts thickness measurements |

| Quality assurance servive | ・Major manufactures quality assurance (3D mesurement CMC visual Inspection,record keeping,shipping,packaging |

|---|---|

| ・Third party non-destructive testing services for small and midium-sized manufactures | |

| ・Outsourcing dimension measurement setvice for precision machined parts by a metal parts manufacturing companies |

| Dispatch of inspectors | ・Overseas dispatch of non-destructive inspectirs |

|---|---|

| ・On-site support and dispatch of non-destructive inspectors for various plant periodic Inspection projects | |

| ・Outsourcing non-destructive Inspectors and technical staff dispatch support to major Inspection companies |

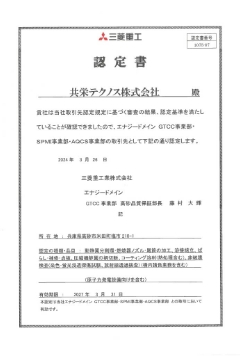

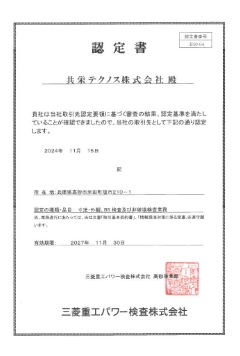

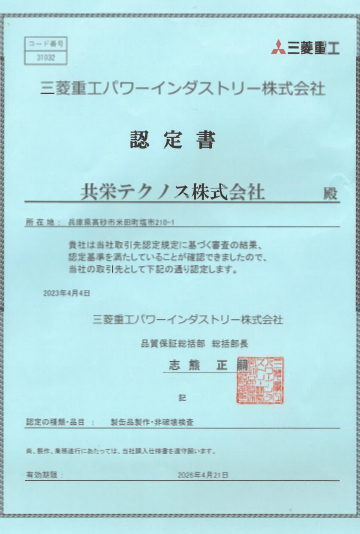

We have certification for inspection services for major manufacturers.

We have extensive experience in inspection services with major manufacturers.

We have been certified for a long period of time.

We provide reliable work in both quality control and quality assurance.

-

Mitsubishi Heavy Industries,Ltd.

-

Mitsubishi Heavy Industries Power Inspection Technologies,Ltd.

-

Mitsubishi Heavy Industries Power IDS Co.,Ltd.